Pre-machining

- Pre-machining

- Hog-outs, window or large deroughing

- Square-up all 6 sides to 5 thousands.

- Add lifting lugs/holes

- Pre-machining to within 1/8″ of finish or tighter

PARPAS XS-84 MILLING CENTER

- Table and machining enclosure

- Avio machining heads (2 different ones)

- Renishaw Probe for full dimensional reports

- Accuracy to 5 microns

TABLE AND MACHINING ENCLOSURE

FIXING METHOD

- T-Slot table for easy clamping

DIMENSIONS CAPACITY

- 8 Meters long

- 4 Meters widht

- 1,5 Meters high

CAPACITY

- 15 000 Kg per square meter of surface

HIGHLIGHT

- Overhead gantry

- Temperature controlled for dimensional stability

BASEMENT

- Completed civil works with 300 square meters of concrete

AVIO MACHINING HEAD

2 SPINDLES

- Electro-spindle 24 000 RPM & 15 000 RPM

TOOL CHANGER

- Automatic Tool Changer with 128 positions (64 x HSK-63 & 64 x HSK-100)

LASER TOOL PRESETTER

- High precision laser system for verifying tool length, diameter and broken tool while rotating

TWIN TOOLS

- Twin tool management system with automatic changes

AXYS

- Z: RAM

- C: Head holding plateform with endless rotation

- A: Spindle body

COOLANT

- Through spindle coolant

- Flood coolant is external of the spindle

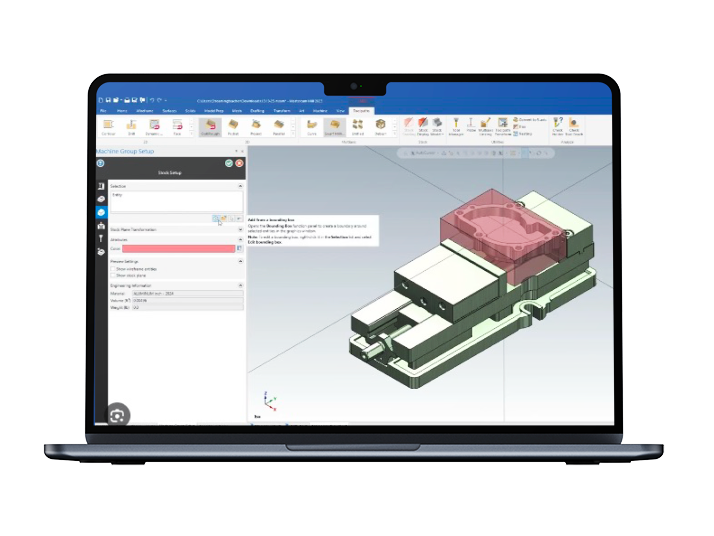

SOFTWARE

PROGRAMMING

- Mastercam software

SIMULATION

- 3D CAD modelling of the part and our machining via our simulator, to ensure there will be no issues prior machining

- Possibility to simulate machining to ensure the performance

CAPACITY

- Full 5-axis programming

DIMENSIONAL INSPECTION

- Linked with the probing device for the inspection report

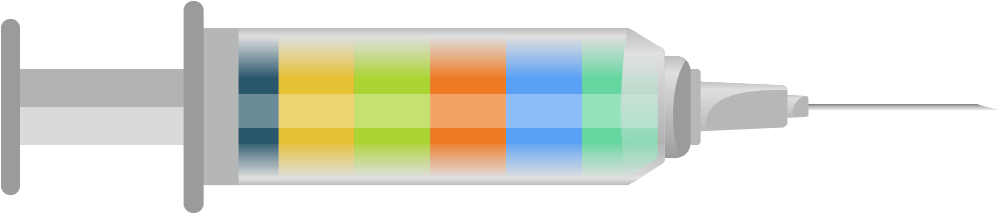

PROBING DEVICE

01

- Renishaw RMP-60

02

- Can be included in the programming for the verification of the steps/file

03

- Linked with software for dimensionnal inspection report

04

- Radio signal transmission

ACCURACY

VOLUMETRIC

+- 0,02 mm

REPEATABILITY

+- 0,10 mm

POSITIONING

+- 0,01 mm

MERCURY

These values are theoretical – Valide only in perfect conditions

VALUE PROPOSITION

-

Hog-Out or Pre-Machining

-

Reduces lead-time for end user/Increases throughput

-

Reduces the weight that must be handled, especially if the blocks are flipped for maching the underside

-

Less chip handling for our customers and a better recovery rate offered by PCP for the chips, lowers the total cost of the aluminium content in your project

-

Differentiates PCP distributors in big-block